What Affects the Cost of an Overhead Crane Inspection? [2025]

Find out the factors impacting the cost of an overhead crane inspection. We will also cover inspection requirements and what you need to do to prepare for an upcoming inspection.

One of the quickest ways to halt production and lose money at your facility is a faulty overhead crane.

Overhead cranes can be found in variety of industries, and they can cost tens of thousands of dollars if you include add-ons and installation fees. However, if cared for properly, overhead cranes can last decades upon decades, making them a long-term investment for the betterment of your organization. In fact, we’ve seen cranes installed in 1940s and 1950s still running. To achieve this, however, you must consistently inspect and maintain overhead cranes. But how much will it cost you?

At Mazzella, we’ve installed, serviced, and repaired thousands of overhead cranes at sites across North America, and we understand that keeping up with an inspection cadence and OSHA standards for your overhead cranes can easily fall on your to-do list.

Whether you’re just getting your inspection program off the ground, or if you’re thinking about switching companies, you might be wondering how much you can expect to pay. After talking with our overhead crane experts, we wrote this article to help you understand what goes into the cost of an overhead crane inspection. We will cover several topics, including:

- How Can Your Facility Prepare for an Overhead Crane Inspection?

- Why Choose Mazzella for Your Next Lifting Project?

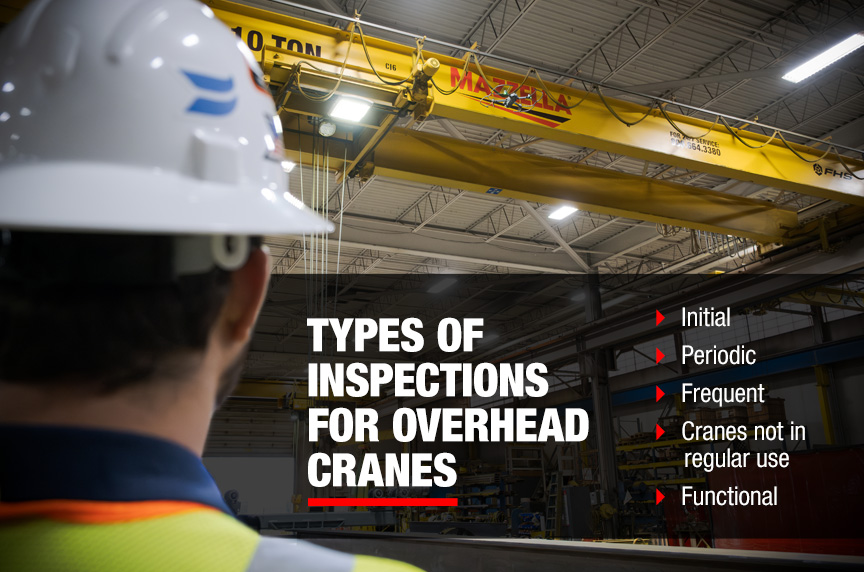

What Inspections are Required for Overhead Cranes and Hoists?

There are five types of overhead crane inspections:

Daily / Initial Inspections

These are performed by the operator at the beginning of each shift or lift.

Frequent Inspections

These are functional and operational inspections performed daily or monthly. The inspection frequency is based on service, environmental, and application factors, as designated by a qualified person. Frequent inspections must be documented.

Periodic Inspections

A detailed functional and operational inspection where individual components are examined to determine their condition. Inspection frequency can be quarterly to annually, and is based on service, environmental, and application factors, as designated by a qualified person.

A crane that is in a normal service class may only need a periodic Inspection once a year and frequent inspections semi-annually. Cranes in heavy or severe service classes should have a frequent inspection performed, at a minimum, on a monthly basis and need periodic inspections done at least 2-4 times a year. Periodic inspections could also be monthly based on usage and duty cycle. Documentation is also required.

Cranes Not in Regular Use

Cranes not in regular use will require additional inspections depending on the length of time they have been out of service.

Functional Test Inspection

A functional test verifies the crane is operating according to it design and manufacturer requirements.

OSHA Requirements for Overhead Crane Inspections

Frequent and periodic inspections are an OSHA requirement, outlined in OSHA 1910.179.

OSHA also requires companies to document their overhead crane inspections. They also have jurisdiction through the General Duty Clause, which, to ensure safe working conditions, gives them authority to fine you for violating updated ASME standards, ANSI standards, and manufacturer recommendations, even if that standard isn’t in OSHA’s guidelines.

The top citations for overhead cranes, or any lifting equipment, include:

- Non-legible capacity markings, which would be on the bridge and the hoist load block

- Wire rope damage

- Pendant labels and condition

- Lack of documentation of frequent and periodic inspections

- Improper grounding for electrified overhead crane systems

Crane inspectors are checking components for proper operational functionality, making brake adjustments, checking contactor controls, greasing bearings, and lubricating wire ropes, and more.

How Much Does Mazzella Charge for an Overhead Crane Inspection?

Mazzella, like most overhead crane inspection companies, uses a base hourly rate that factors in the cost of our:

- Technicians and labor

- Trucks, trailers, and overall transportation

- Man lifts

- Equipment

- Training and expertise

Mazzella’s standard advertised rate is $150 an hour. But the cost of a crane inspection will also depend on the type of cranes at your facility and the number of cranes that need to be inspected and the accessibility to those cranes.

Are There Hidden Fees or Costs?

Mazzella’s inspection team uses a fixed price when quoting companies. It is rare for the inspectors to add on fees or costs later. If there’s something that would cause additional costs, the team would always talk with the customer prior.

Pricing Between Frequent Inspections and Periodic Inspections

Frequent inspections are considerably less expensive than the periodic inspection, as they’re not as detailed and take less time to complete. It takes roughly half the time to do a frequent inspection versus a periodic depending on the crane type and the usage of the crane.

What Factors Impact the Cost of an Overhead Crane Inspection?

The size and complexity of the crane and accessibility are the biggest factors with inspection pricing.

Most standard cranes in a machine shop or a dye handling facility—40-ton capacity and below—will only take a couple of hours to inspect. A standard chain hoist could take less than 30 minutes to inspect.

However, larger crane have more components to check and may require multiple inspectors. Those inspections could take a full day or even several days to finish, which will increase the cost of your inspection. The inspection process on a larger crane, especially older models with DC crane controls, could take two inspectors up to six or eight hours to complete.

Regarding accessibility, if you have a jib crane in your shop that can be easily reached using a step ladder or small lift, that will speed up the inspection process and lead to a lower cost. However, an overhead crane in a mill with a 100-ton lifting capacity would require you to shut down parts of the plant. It would also require inspectors to go on large man lifts and catwalks. In this scenario, it could take inspectors an hour to even reach the crane.

Can Mazzella Inspectors Make Repairs on Site?

Yes, if your company has spare parts on hand, or our inspectors have the parts on their truck, our inspector can make that repair while on site. But this also depends on the extent of the repair. Sometimes, a more extensive repair will call for another visit. One advantage to doing smaller repairs on site is it will save you from having to schedule another visit.

These repairs, however, are not included in the inspection cost, and would result in additional parts and labor costs.

Can You Create a Reoccurring Overhead Crane Inspection Schedule?

Many crane inspection companies will work with you to set up a reoccurring inspection schedule. Mazzella has many clients that set up on a monthly frequent inspection schedule, with periodic inspections spread out over a calendar year. In fact, setting up a reoccurring inspection schedule would make the most sense for organizations who use a crane in their daily operations.

If you’re interested in doing a long-term inspection schedule (two or three years in advance), you can negotiate pricing with your inspection provider.

Will a Facility Need to Shut Down for an Overhead Crane Inspection?

During the inspection, the crane would have to be out of service or offline, depending on their usage. If there are multiple cranes on a single runway, the inspectors would need to shut down the entire runway or isolate the crane being inspected.

But if you’re not capable of a complete runway shutdown, you can plan with your crane inspector to work on temporary end stops, where you can have a single crane out of service while doing the inspection and still have access to the rest of the runway.

But, generally, the crane must be out of service for an inspection to proceed.

How Can Your Facility Prepare for an Overhead Crane Inspection?

The safety of the crane inspectors and your employees is the number one priority during any visit.

To help with this effort, ensure the crane inspectors can easily access the cranes. Clear any debris out of their way, inform employees and managers before the inspectors arrive, and make sure your cranes are out of service. To speed up this process, reach out and do pre-work planning with your inspection provider.

What Makes Mazzella’s Crane Inspectors Qualified?

For somebody to meet OSHA’s crane inspection qualifications, they have to have a minimum of 2,000 hours of industry-relevant experience. Mazzella’s crane inspectors far exceed this requirement.

Mazzella requires all our inspectors to enroll in a Certified Inspectors course, and then we have them work with another experienced qualified inspector before they go out on their own. So, they’ve got the industry experience, they’ve got the formal training, and they’ve got hands-on training with another experienced inspector.

Mazzella’s crane inspectors are also incredibly knowledgeable about relevant OSHA, CMMA, ASME, and other industry standards, and they will reference those standards while performing the inspection, ensuring you’re in total compliance.

Several days after the inspection is done, Mazzella’s inspectors will provide you a digital copy of an OSHA-compliant inspection report. You can also print off this report to have a physical copy. These reports usually take between two to five days to complete, depending on the complexity of your crane.

A Mazzella representative will reach out to you and go over the report to make sure you understand any issues reported and how they affect your compliance, safety, or the general operation of your crane. Any immanent concerns or conditions that are found will be discusses with the site contact as they are discovered.

Why Choose Mazzella for Your Next Lifting Project?

We hope this article gave you the information you need to properly plan and budget for your crane inspections.

Another advantage that Mazzella offers is we can offer customers a discounted package rate for all our inspection offerings. So, instead of contacting four different companies for your warehouse, rigging, fall protection, and overhead crane inspections, you can get all of them through Mazzella. Mazzella also offers world-class material handling training in a variety of formats and settings. Visit our training page to learn more.

With over 70 years in the lifting and rigging industry, Mazzella is a one-stop-shop for your organization’s material handling needs. Whether it’s overhead crane inspections, overhead crane installation, design, and manufacturing, warehouse rack inspections, fall protection, lifting and rigging training, lifting slings, rigging hardware, or below-the-hook lifting devices, get in contact with one of our associates to learn more.

Schedule your next overhead crane inspection today.

Copyright 2025. Mazzella Companies.