Five Reasons You Should Invest in an Enclosed Track Fall Protection System

Enclosed track fall protection systems are an excellent option for workers, but are they worth the extra money? We cover five benefits you should consider during your research.

Do you need a new fall protection system at your facility, but don’t know which system is best for you?

It’s understandable. There are plenty of options to choose from, including cable lifeline systems. However, while they are affordable, cable lifeline systems are not ideal for all work environments, as they have a tendency to corrode, stretch, and sag over time.

In many applications, an enclosed track fall protection system would be a better fit. They are incredibly safe, easy for workers to use, and have many customization offerings, but some companies may be weary of the initial high price tag and the installation requirements.

At Mazzella, our Fall Protection team has installed hundreds of fall protection systems in all types of indoor and outdoor environments, and they think enclosed track systems are one of the best available systems. Today, we will discuss the five reasons why you should invest in an enclosed track fall protection system, all while answering important questions you may have during your research.

Here is what we will cover:

- What Is an Enclosed Track System?

- What Industries Could Use an Enclosed Track System?

- What are the Five Biggest Benefits of an Enclosed Track System?

- Why Would You Choose an Enclosed Track System Over a Wire Rope System?

- What Affects the Pricing for Enclosed Track Systems?

- Final Thoughts

What Is an Enclosed Track System?

Enclosed track systems are permanent fall protection systems commonly used in high-level, repetitive manufacturing and maintenance environments. These systems are comprised of:

- Trolleys that travel on wheels inside the system

- Covered tracks that protect the trolley and offers minimal resistance

- Hanger assemblies and track splices

- A body harness that provides a connection between the worker and the enclosed system

Usually made from steel or aluminum, these systems can be used in indoor and outdoor applications, and they can be either free standing or mounted to a ceiling.

Enclosed track systems are also an ideal choice for anyone working in low headroom applications.

Why Would You Choose an Enclosed Track System Over a Wire Rope System?

Wire rope systems have a place in certain work environments. They are great options for construction and excavation companies who are working at temporary job sites, where an enclosed system would take too long to install.

However, your capabilities are restricted compared to an enclosed system, especially regarding customization offerings and safety.

What are the Five Biggest Benefits of an Enclosed Track System?

Ease of Use for Your Workers

The rolling trolley design makes enclosed track systems easy to use for workers, reducing resistance and giving them flexibility to move around long distances. Since multiple workers can be attached to the same track, this also increases their productivity.

Suitable for Outdoor and Harsh Work Environments

The enclosed track design prevents dust and debris from interfering with the rolling mechanism, making it well-suited for industrial environments.

Improved Rescue Capabilities

Enclosed track systems come with a special trolley with a brake that helps prevent the worker from rolling away if they fall, enabling quicker rescue and self-recovery. Ensure your organization has a working from height rescue plan in place to stay OSHA and ASME compliant.

Reduced Risk of Secondary Injuries

If somebody falls in the enclosed track system, the fall is just the distance the lanyard allows you to fall. The enclosed track design reduces swinging and fall distances. Whereas on a lifeline, you’re going to fall the distance the lanyard allows you to fall, and then whatever flex is in that lifeline. Wire rope lifelines sag when a worker falls, increasing the risk of secondary injuries for workers.

Less Maintenance

If you do have an incident, you take the trolley that was used out of service and inspect it. And if there was no damage to the trolley, you could put it right back in service. Whereas in a lifeline, you will need to replace the entire system.

Bonus Benefit: Cost Savings Over Time

With less maintenance comes more cost savings in the long run. Instead of having to replace a wire rope system three times in four years, you are better off paying the initial high costs of an enclosed track system and avoiding constant maintenance and replacements.

What Industries Could Use an Enclosed Track System?

Any industry involved with high-volume manufacturing, or any industry where workers must work from height, would benefit from having an enclosed track fall protection system.

According to OSHA, any company in general industry working from a height of 4’ or greater—6’ for construction applications—must provide fall protection for their employees, so enclosed track systems could be used almost anywhere.

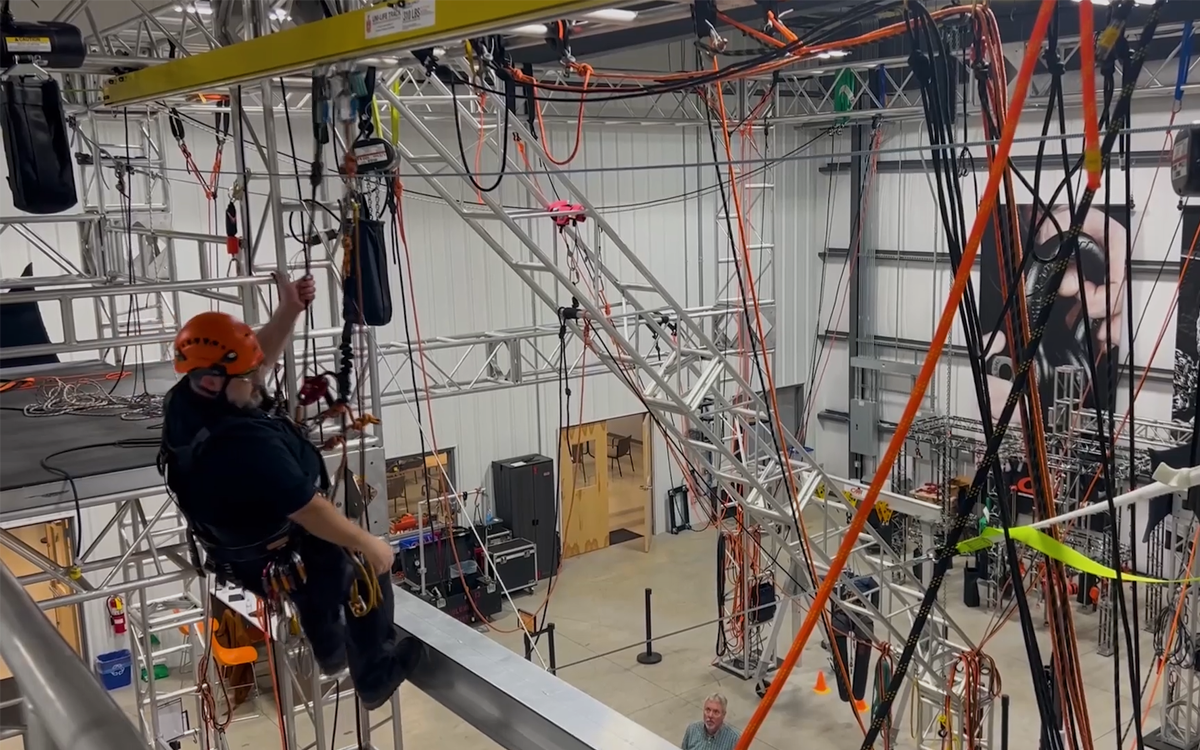

Maintenance workers in the railroad industry can use enclosed track systems to better protect them in railyards when servicing railcars and locomotives. They can be used in the aerospace industry to service wings. You could see them in defense manufacturing facilities to service and inspect tanks and trucks. Enclosed tracks are also popular in the entertainment industry to design sets, repair video walls, maintain stage assemblies, and facilitate production.

In one example, Palm Harbor Homes, a major modular and mobile home manufacturer, worked with Mazzella’s Fall Protection team to install an enclosed track system to keep their employees safe while working at height.

Training for Enclosed Track Systems

Workers must be trained when using any fall protection system, including enclosed tracks. During training, users will learn:

- The procedures to use the enclosed track they have installed

- The daily inspection criteria

- Signs of concern (damage)

- Limitations of the system

What Affects the Pricing for Enclosed Track Systems?

Enclosed track systems can be as complex or simple as you need them to be. With so many customization offerings (curved tracks, passable systems, galvanized tracks), the price of your system can vary.

According to our specialists, an enclosed track system will cost anywhere between $70-$100 per foot just for the rail alone. In one example, a customer ended up paying over $400 a foot after add-ons. Also, some companies will need structural enhancements to their facilities to install these systems, which will drive up the final cost.

Where are Enclosed Track Systems Not a Good Fit?

Enclosed tracks can take a decent amount of time to construct and install at a facility, so companies working in temporary projects would be better off installing standard lifeline systems.

Final Thoughts

We hope you learned more about the biggest benefits of an enclosed track systems and how it can benefit your organization.

Regarding fall protection systems and keeping your employees safe at height, you want the best system, not the most affordable system. On top of a proper fall protection system, your workers need proper fall protection training.

At Mazzella, our Fall Protection team offers knowledge-based basic and competent person fall protection training for workers, and we also know how complicated it is to stay updated on fall protection standards and requirements.

With decades of experience in inspecting, installation, and training, Mazzella can be your one-stop-shop for all your fall protection needs. Contact a team member today if you have any questions about enclosed track systems.

Also, read our case study to learn how an enclosed track system helped Palm Harbor Homes improve safety and efficiency for their workers.

Copyright 2025. Mazzella Companies.